Metal embossing machine

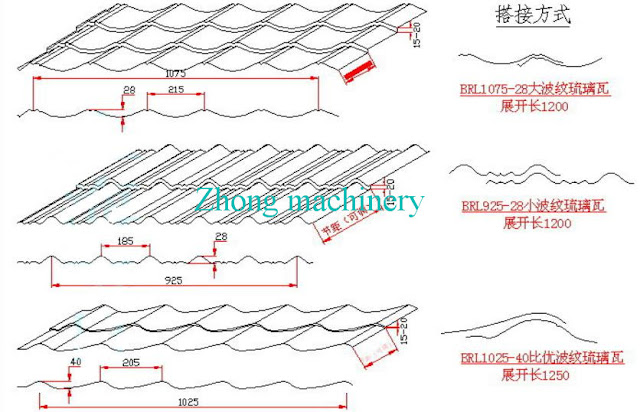

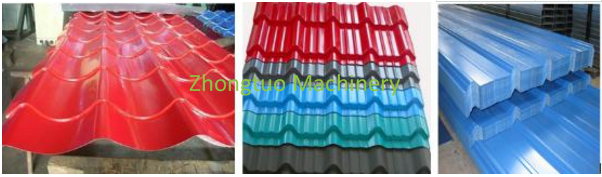

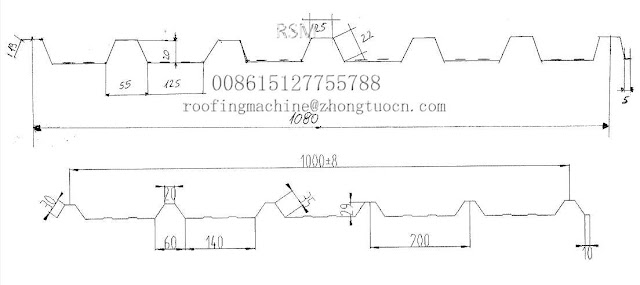

Metal embossing machine takes advantage of cold roll forming principle to make various types pictures on the metal. The material thickness could be from 0.2 to 1.2 mm. The material could be Aluminum (Lv Bo), forming embossed decorative aluminum strip, color coated steel plate, hot galvanized plate, copper plate, cold-rolled plate, stainless steel plate and others. For the embossed metal sheet could be at the following places: Kitchen cabinets, appliances, freezer, refrigerator, building facades, roof tiles, elevators, compartment floor, door manufacturing, corridor anti-skid, machinery and other industrial applications, pressing plate pattern not only beautiful patterns, uniform, three-dimensional sense of strong, also increased part of the plate thickness and strength. Here are some finished product pictures for your reference: Take one of the drawing profiles for your reference: Here is the machine picture for your reference: Embossing Machine Main Paramet