Metal floor decking machine

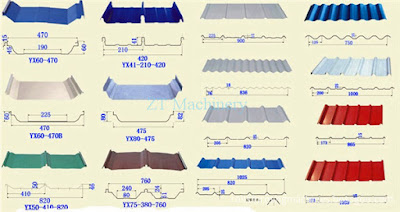

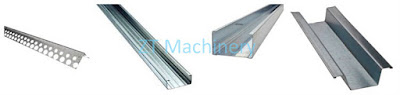

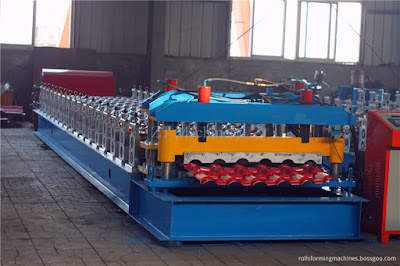

We are specialized in designing and building various Metal floor decking machine, such as close-type Metal floor decking machine, 3-waves Metal floor decking machine, 2-waves with ribs Metal floor decking machine etc. In mod ern time, people prefers to use steel instead of stone or cement for construction projects, such as the steel floor decks, because it is more convenient to fill the concrete into the steel floor deckings than to use the stone floor. Main parameters of Metal floor decking machine: Thickness of Material: 0.7mm-1.2mm Machine working speed: 8-12m/min Feeding Guide of Metal floor decking machine: 2 Rollers to guide the material into the machine Both ends of the flat adopt bearing structure Main roll forming machine of Metal floor decking machine: Dimensions: 11500mmx1500mmx1300mm Roller Stations: 22 stations Diameter of Shaft: 90mm Material of Shaft: 45# steel Material of roller: Gcr15 Forming speed: 8-12m/min Siding Plate: 350 H S