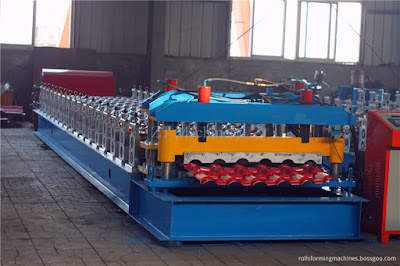

Glazed tile roll forming machine

Glazed Tile Roll Forming Machine is widely used for the roofing panel. Glazed tile has a beautiful appearance, simple and elegant, sophisticated styling,

noble taste and other characteristics, can be widely used in garden plants, scenic spots, pavilions, hotels, villas, galleries, resorts, home and other buildings, and beautiful and durable.

Each part and quantity of Glazed Tile Roll Forming Machine

1. Material Spec: Q235; Thickness: 0.4 mm to 0.6 mm

2. Manual decoiler Max. Capacity: 5000kgs

3. Controlling system: PLC

4. Main machine power: 5.5kw;

Hydraulic station power: 5.5kw

5. Coil width : 1250 mm

Step height: 30mm

6. Working speed: 3-5m/min

7. Type of cutting: length-set cutting

8. Power: 380V/3pH/50Hz or at the buyer′s requirement

9. number of rollers:13

10.Diameter of shafts: φ 80 mm

11.Material of shafts: 45# steel

12.Material of rollers: 45# steel, surface hard chromium plating.

13.Frame : 350 mm H beam steel welded

14.Voltage: 380 V/50 HZ 3 Phase or as your required

15.Weight of main part: 4. 5 tons

16.Size of the main part: 7500*1650*1500mm

17.Roller fixer : middle plate

13.Frame : 350 mm H beam steel welded

14.Voltage: 380 V/50 HZ 3 Phase or as your required

15.Weight of main part: 4. 5 tons

16.Size of the main part: 7500*1650*1500mm

17.Roller fixer : middle plate

18.Drive mode: case of differential

19.Material of blades: Cr12 quenched

20.Brand of PLC and converter: Delta or Siemens

19.Material of blades: Cr12 quenched

20.Brand of PLC and converter: Delta or Siemens

21.Encoder: Omron

22.Products receiving tables: 3 m/set with 2 sets

22.Products receiving tables: 3 m/set with 2 sets

No. Name Unit Qty of Glazed Tile Roll Forming Machine

1 Manual decoiler Set 1

2 Leveling beach by manual adjustment set 1

3 Main forming machine set 1

4 step formed mechanism Set 1

5 Shearing system with one cylinder set 1

6 PLC control system set 1

7 Hydraulic pump station set 1

8 Motor drive set 1

9 Output table set 1

Comments

Post a Comment