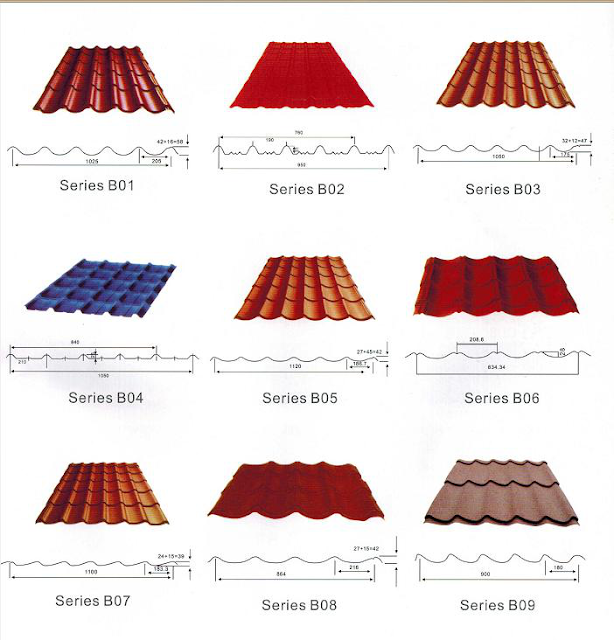

914 corrugated steel roof sheet roll forming machine

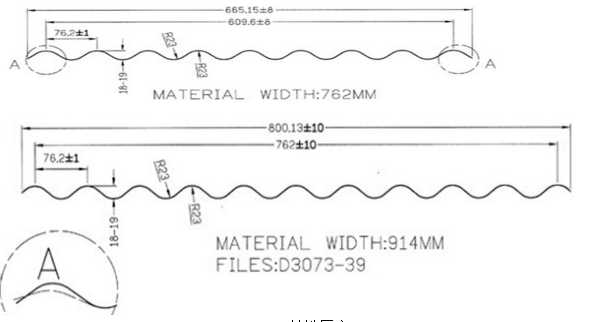

914 corrugated steel roof sheet roll forming machine can make two types corrugated steel roof sheet. The input coil can be 914 mm and 762 mm. Just adjust the width of input coil then you can get two types corrugated steel roof sheet. Here is the profile for your reference: Coil material thickness:0.2mm--0.3mm (0.2mm is the standard for the trial run) Processing Material Input Width(mm): 914mm/762mm Features of corrugated steel roof sheet (1)Can be used in a variety of applications (2)Ideal for protection against wind, heat, humidity, & water (3)Made from durable galvanized steel Here i will show you some parameters of the 914 corrugated steel roof sheet roll forming machine. 1).Roller station:22 stations 2).Shaft material:45# steel,high frequency surface treatment and grinding process; Outer diameter:75mm Roller material: 45#Steel heat treatment HRC50 and surface is being hard chrome. 3).Transmission:Chain Driving and Gears 4).Forming Speed: 20m/min 5