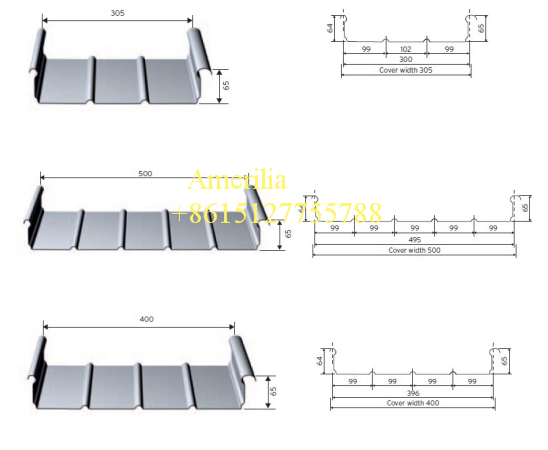

Trapezoidal roofing sheet roll forming machine

A trapezoidal roofing sheet roll forming machine is a regular metal sheet roll former that produces metal roofing sheets or roof panels for both individual and industrial building. Trapezoidal roofing sheets are the most popular metal roof panels not only for residential buildings but also for commercial or industrial buildings. There are so many different profiles for a variety of applications. Here is the drawing profile of trapezoidal roofing sheet you can have a check: Sometimes when a client needs to produce trapezoidal roofing sheets with different effective widths with anything else remained the same. In this case, the investment shall be made on only one machine, because a trapezoidal roofing sheet roll forming machine is always adjustable for different feeding widths. This means you can make trapezoidal roof sheets with different effective widths from different-width materials. However, a client must need two trapezoidal sheet roll forming machines for manufacturing two