Width adjustable glazed tile roofing sheet roll forming machine

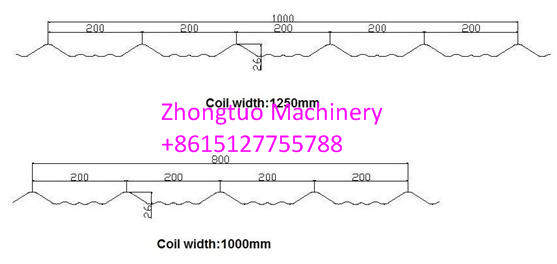

Width adjustable from 800 to 1250 mm glazed tile roofing sheet roll forming machine could be used to make various types and sizes roofing sheet in the glazed types. All the machines could be customized according to the customer requirements. In the following article, I just show you one example about how to make adjustable width type glazed tile roofing sheets fully autoamtic. Take the following two drawing profile for example: Processing material: colored steel plate, galvanized plate, or aluminum plateMaterial thickness: 0.3---0.8mm Material hardness: 195 mpa---350 mpa Material width: 1200mm Formed width: 1000mm Wavelength: 200mm Step height: 24mm Step length: 150mm---380mm (adjustable) forming speed: 8-12m/min The machine picture of adjustable width roofing sheet making machine for your reference: Here are more details pictures for your reference: Here is Width adjustable from 800 to 1250mm glazed tile roofing sheet roll forming machine basic para