Double layer roofing sheet machine for Bolivian customers

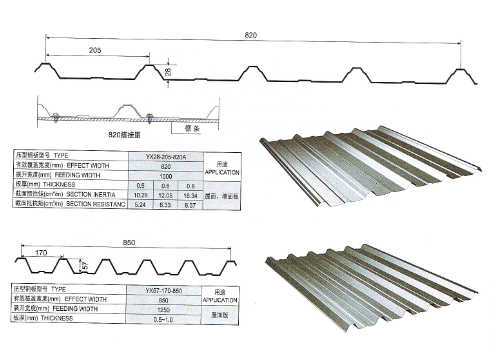

A double layer roofing sheet machine for Bolivian customers has finished according to customer's requirements. The upper layer is corrugated metal roofing sheet machine while the down layer is trapezoidal metal roofing sheet machine. Parameters of the double layer roofing sheet machine Feeding width:1220mm depends Material thickness: 0.3-0.8 mm Roll station: depends Motor power: 5.5+4 kw Productivity: 0-12 m/min Roofing sheets of the double layer metal roofing sheet machine The feeding coil part of the main machine The cutting part of the double layer roofing sheet machine We also send the testing video to the customer. If you also have the requirements about the metal roofing sheet machine, we can customize it for you. Meanwhile we can provide you more professional advice for buying a suitable machine. You can contact with us about the detail information. Email: machinesale01@zhongtuocn.com