Roof ridge cap making machine

Roof ridge cap making machine can make roof ridge cap in batch with a stable speed. This machine adopts the arch type, which increases the firmness of the machine while making the machine more beautiful. At the same time, there is electric box control and easy button control, which makes it easier to operate the machine.

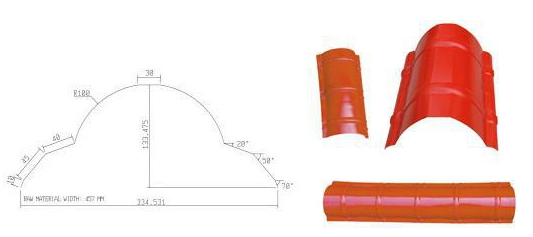

A random drawing profile of roof ridge cap

Supporting material thickness: 0.4 to 0.8mm

Forming speed: 3-5 m/min

Roll station: 12 stations

Motor power: 4+4 kw

Productivity: 3-5 m/min

Machine weight: about 3.5 tons

Forming speed: 3-5 m/min

Parameters of roof ridge cap making machine

Material thickness: 0.4-0.8 mmRoll station: 12 stations

Motor power: 4+4 kw

Productivity: 3-5 m/min

Machine weight: about 3.5 tons

Features of roof ridge cap making machine

1. The equipment control is PLC control, and multiple safety protection is set during normal production.2. The equipment is welded steel plate. It is also tempered to eliminate internal stress and avoid deformation of the fuselage.

3. The forming frame is cast iron structure and tempered. High strength and long service life.

4. The material of the roll shaft is 40Cr, and the hardness is HB280 after quenching and tempering treatment.

5. The material of the roller is GCr15, quenching treatment, hardness: HRC 56-62 °C.

Comments

Post a Comment