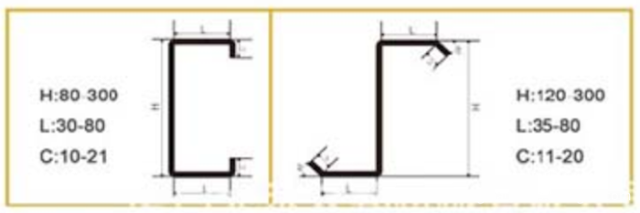

Combined C stud and U track Machine

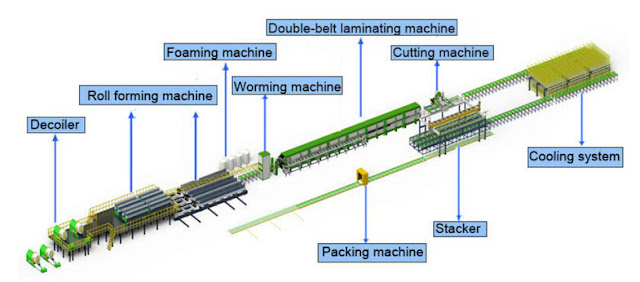

Profiles for drywall constructions are C- and U-shaped profiles (stud and track), which are used to construct a metal frame to provide support for plasterboard and gypsum panels. They are, however, highly technical profiles and must satisfy precise operating characteristics, complementing each other perfectly to form a high quality, robust framework. Combined C stud and U track Machine allows you to make U track and C stud by one machine. By this way, one worker can operate two sets machine easily. Here are some stud and track drawing profiles for your reference: Combined C stud and U track Machine parameters for your reference: Combined C stud and U track Machine pictures for your reference : here is also the video for your reference: CONTACT INFORMATION: Email: roofingmachine@zhongtuocn.com Whatsapp: +8613733275488