EPS rock wool sandwich panel production line

EPS Rock Wool Sandwich Panel Making Machine including unwinding, before cutting, film, beading / molding, rock wool and spray delivery, Edge foam, continuous curing, cutting and other functions, high degree of automation, stable performance.Edge polyurethane foam systems, automatic feeding system, to ensure that the raw material requirements in full accordance with the ratio of mixing, spray evenly; using a reliable foam technology to ensure uniform sheet foam, dense, sheet closely connected.The production line is equipped with automaticcontrol system, userfriendly interface for easy operation, monitoring, advanced computer control, easy to adjust the entire line of argument, effectively ensure the production line stable and efficient operation.

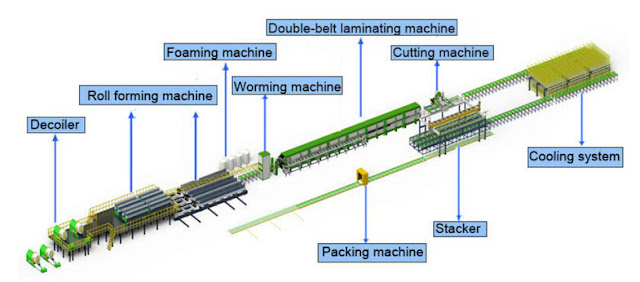

rockwool sandwich board production line production Process:

(The upper)Dncoiler ---Cutting ---Film---Beading---Roll forming \

--Rock wool delivery--Glue--Sealing side foam-- laminating machine with Foam,Solidify,Roll forming--Cutting --Run-out table

(Lower part)Uncoiler ---Cutting →Film→Beading→Roll forming

Parameters of sandwich panel roll forming machine :

Raw material

- Coil thickness:0.4~0.6mm

- Coil weight:Max 5T

- Coil width: Max 1250mm

- Coil inner diameter:ø508mm

Un-coiler

- Bear weight:5T

- Mandrel expansion :465 – 515 mm

Laminating machine

- PVC coil outer diameter:300mm

- PVC coil inner diameter:70-82mm

- Maximum coil width:1250mm

Beading Equipment

- Speed:10m/min

- Power:2.2kw or according to the profile

- Power supply:motor

- Material of roller:l 40Cr quenched and tempered, chrome

Roll forming

- Frame:Cantilever structure

- Speed:10m/min

- Power:4kw up, 7.5kw down

- Shaft diameter:50 mm

- Distance roller head:350mm

- Rollers: 11 up, 18 down

Rock wool delivery device

- Motor Power:2*1.5Kw

- Speed:8m/min

- The maximum transport width:1200mm

- Dispensing Systems

- Effective volume:150L

- Unit motor power:10KW

Roll forming machine

- Length:10mm

- Width:1200mm

- Lifting speed:200mm/min

- Drive motor power:2.2Kw*4

- Lifting motor power:1.5Kw*4

Cutting part

- Cutting motor power:7.5Kw

- Lateral movement motor power:1.1 KW

- Traversing speed:150 mm/s

- Cutting width:1300 mm

- Cutting error:±2mm

Details of rockwool sandwich board production line :

In addition, there is a video for your reference:

CONTACT US:

Email: roofingmachine@zhongtuocn.com

Whatsapp: +8613733275488

Thanks For sharing very helpful information

ReplyDeleterockwool panel