Shelf beam making machine/interlocked square pipe making machine

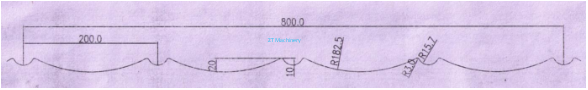

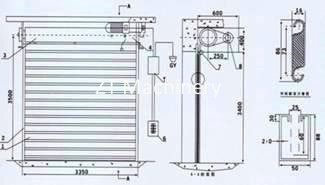

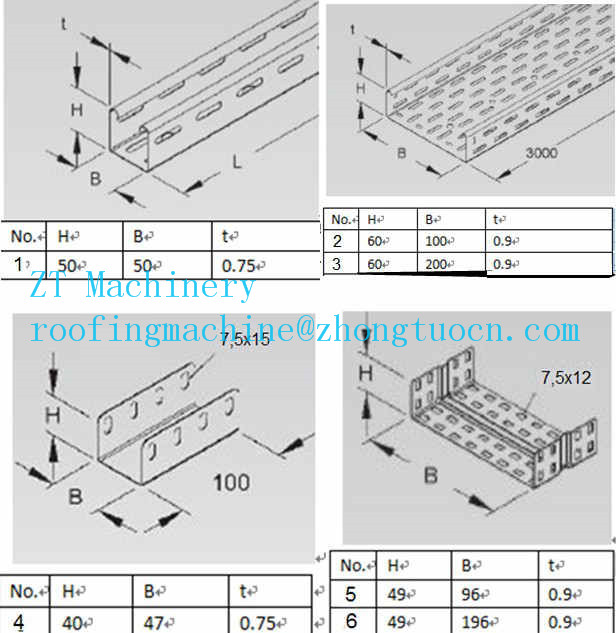

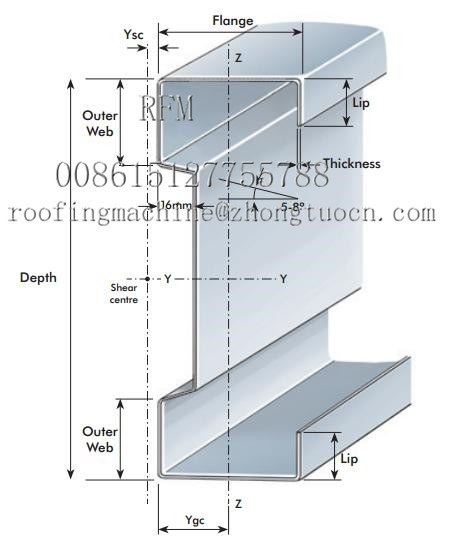

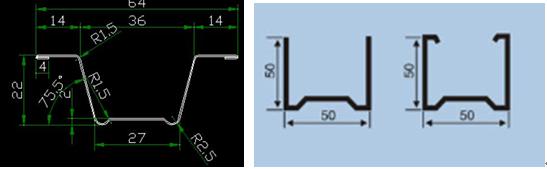

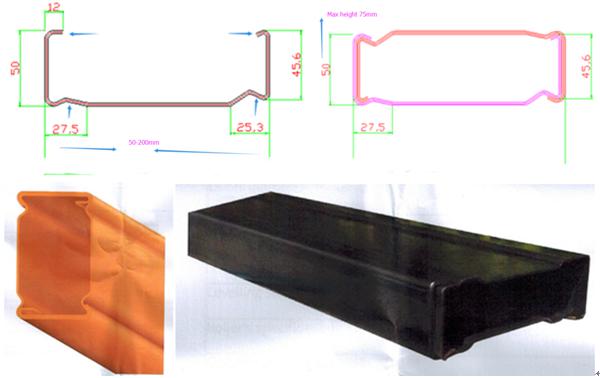

Shelf beam making machine /interlocked square pipe making machine could be used to make the square pipe by two C shape purlines. The machine takes advantage of the roll forming machine principle and interlocked method to make the building used pipes. For those square pipes made by those machine are size adjustable and there is seam. Meanwhile those pipes are also could be used as shelf beam for supermarket or warehouse and others. The box making machine is composed by two parts: one is the specail C shape channel making machine. The second part is interlocked making machine. Here are some drawing profiles and finsihed products pictures for your reference: Here are the details parameters of the Shelf beam making machine for your reference: First part: C shape roll forming machine This machine is composed by the following elements: decoiler, leveling beach, main roll forming machine, shearing system, hydraulic system, and PLC control system and runout table. Manual deco