Double sizes high speed omega channel roll forming machine

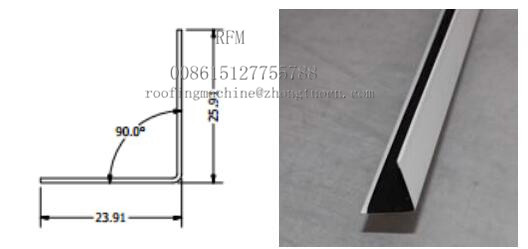

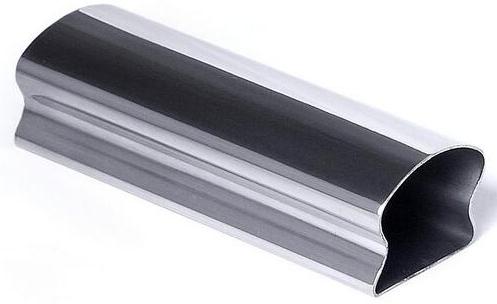

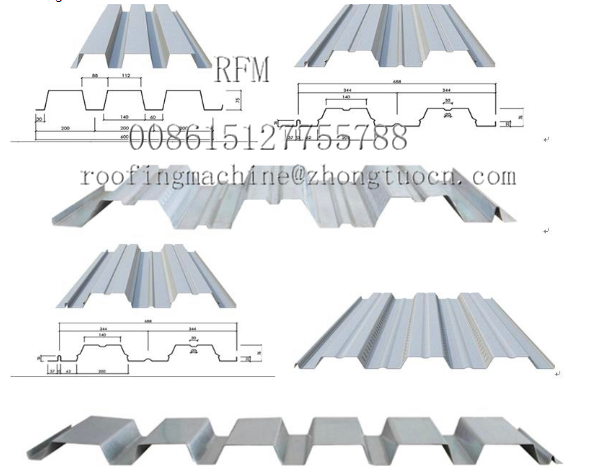

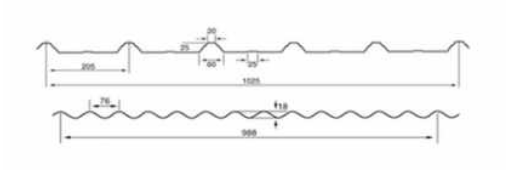

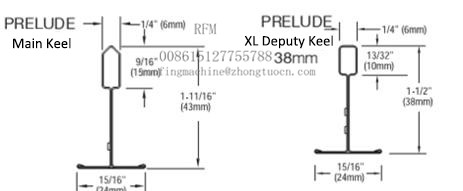

High speed omega channel machine double sizes could be used to make omega channel in large quantity. The working speed could reach 50 m/min. This machine we made for Australia customer is for making furring channel like the following drawings: Profile 1: a = 50mm, b= 24mm, c = 20mm Profile 2: a = 50mm, b= 15mm, c = 15mm The material could be SG350, SG550, stainless steel or normal carbon steel. The machine we designed like the following pictures: Here are some machine parameters for your reference: For this machine, if you need to know more information, please contact us at any time. Email: roofingmachine@zhongtuocn.com Whatsapp: +8615127755788 and +8613733275488