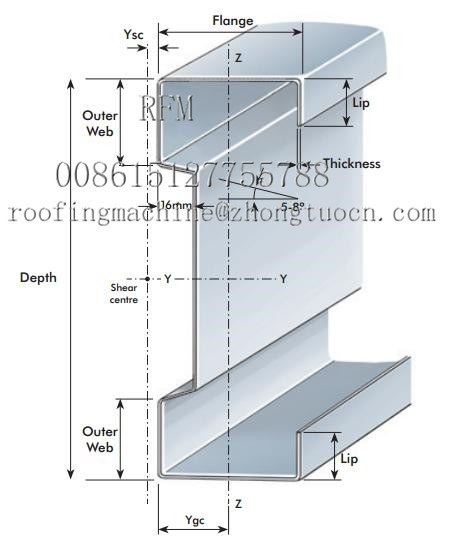

Sigma purline sections are manufactured by cold roll forming pre-hot dipped galvanised steel, grade S450, having a minimum yield stress of 450N/mm2. The top flange of the purlin must have adequate restraint provided by robust steel sheeting (or similar) fixed directly to the top flange.The steel has an external galvanised coating Z275, giving an approximate coating thickness of 20 microns each side. Based on the charactgers of sigma purline, now it is quite popular used in roofing and house building construction area. Based on the market demand, our factroy developed roll forming machines of making sigma purline. By the roll forming machine, the production could be enhanced greatly. By the following drawing profile, let us now check what is Sigma purline section? How the Sigma purline roll forming machine works and how composed? Working process of Sigma purline roll forming machine: Decoiling---feeding---leveling---forming---punching---cutting---production The Sigma pu...

Comments

Post a Comment